Industrial serial LCD displays are a crucial component in many modern industrial systems. Whether used in manufacturing equipment, automation systems, or control panels, these displays provide vital information to operators and engineers. But what exactly are industrial serial LCD displays, and how do they work? Neste artigo, we will delve into the world of these displays, exploring their features, applications, and the technology behind them.

Table of Contents

- What Are Industrial Serial LCD Displays?

- How Do Industrial Serial LCD Displays Work?

- Advantages of Industrial Serial LCD Displays

- Applications of Industrial Serial LCD Displays

- Choosing the Right Industrial Serial LCD Display

- Challenges of Using Industrial Serial LCD Displays

- Future Trends in Industrial Serial LCD Displays

What Are Industrial Serial LCD Displays?

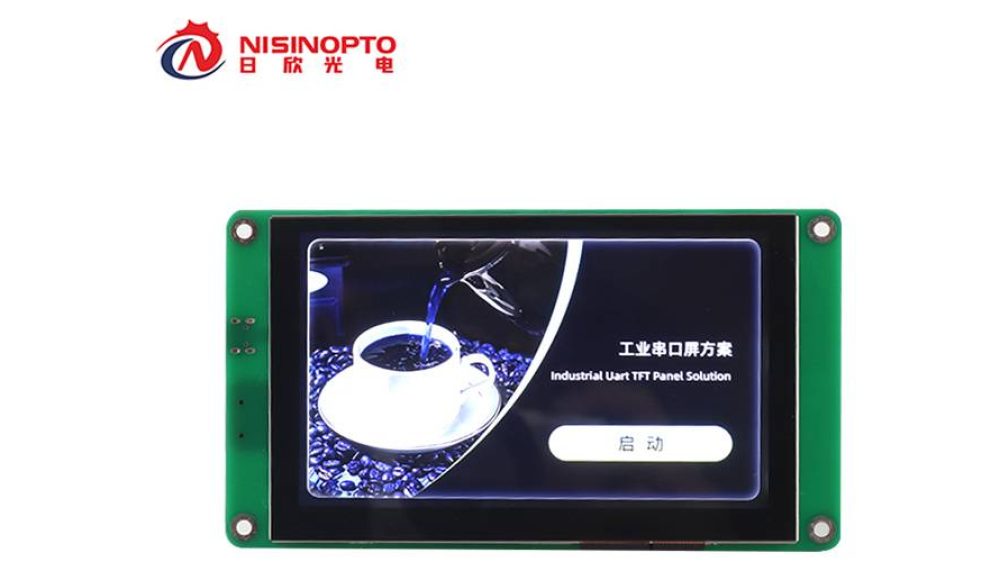

An industrial serial LCD display is a specialized screen that uses liquid crystal display (LCD) technology to present data in a readable format. Unlike regular consumer-grade LCD displays, these are designed for industrial applications where reliability, durabilidade, and ease of integration are paramount.

These displays are typically serial communication-based, meaning they receive data in a sequence (one bit at a time) through communication protocols like RS232, RS485, I2C, or SPI. They are often used in harsh environments such as factories, control rooms, and outdoor settings.

Principais recursos:

- Durability: Designed to withstand industrial conditions such as temperature extremes, dust, and vibration.

- Eficiência energética: These displays consume less power, making them ideal for continuous operation.

- Compact Design: They are often compact and modular, allowing for easy integration into different devices and systems.

How Do Industrial Serial LCD Displays Work?

Serial Communication

Serial communication is a method of data transfer where bits are sent one by one over a single communication channel. This is in contrast to parallel communication, where multiple bits are transmitted simultaneously. Serial communication ensures that data can be sent over long distances with minimal signal degradation.

Types of Interfaces

There are several common communication protocols used for displays:

- RS232: A common standard for short-distance communication, usually between 15 to 50 feet. It’s a simple and inexpensive interface.

- RS485: Used for longer distances (up to 4,000 feet) and multi-point communication, making it ideal for factory automation.

- I2C (Inter-Integrated Circuit): A popular protocol for low-speed data transfer over short distances, often used in smaller embedded systems.

- Spi (Serial Peripheral Interface): A high-speed protocol used for fast communication between a master device and multiple peripherals.

Advantages of Industrial Serial LCD Displays

Eficiência energética

One of the standout features of industrial serial LCD displays is their low power consumption. These displays are designed to be energy-efficient, which is crucial in industrial settings where devices run continuously. The reduced power requirement not only lowers electricity costs but also contributes to the longevity of the display.

Ease of Integration

Because they use serial communication, industrial serial LCD displays are straightforward to integrate into existing systems. The wiring is simpler, and the setup typically involves connecting the display to the controller or device using a single communication line. This is especially beneficial for automation and control applications, where downtime and complexity need to be minimized.

Applications of Industrial Serial LCD Displays

Industrial serial LCD display find use in various sectors, providing real-time data to operators, technicians, and engineers.

Manufacturing Automation

In manufacturing automation, these displays are integrated into machinery and control panels to show the status of processes, machine health, and performance metrics. For instance, a display might show the temperature, pressão, or speed of a production line. This data helps operators monitor and adjust processes in real-time.

Process Control Systems

In process control systems, industrial serial LCD display is often used to display vital operational parameters, such as flow rates, temperature readings, and pressure levels. These displays ensure that operators have accurate, up-to-date information to make informed decisions.

Choosing the Right Industrial Serial LCD Display

Selecting the appropriate industrial serial LCD display depends on several factors, such as the application environment and the specific technical requirements.

Display Size and Resolution

The size and resolution of the display should match the data you need to present. A small, low-resolution screen may be sufficient for basic status information, while larger displays with higher resolution are better suited for complex data and graphical content.

Environmental Considerations

Industrial environments can be harsh, with extreme temperatures, umidade, dust, or vibration. It’s essential to choose a display with the appropriate IP rating (Ingress Protection) to ensure it can withstand these conditions.

Communication Protocols

As discussed earlier, industrial serial LCD display can support various communication protocols. The choice of protocol depends on factors like the distance between the controller and the display, the speed of communication, and the complexity of the system.

Challenges of Using Industrial Serial LCD Displays

While industrial serial LCD display offer many advantages, they do come with some challenges:

- Limited Color Options: Many industrial displays are monochrome, which may limit their ability to convey information visually compared to full-color screens.

- Compatibilidade da interface: Not all industrial systems support the same communication protocols, so compatibility issues may arise when integrating displays with older or specialized equipment.

- Size and Visibility: In some environments, the display may need to be large enough or equipped with enhanced visibility features like backlighting or sunlight readability.

Future Trends

À medida que a tecnologia avança, industrial serial LCD display is likely to become even more robust and feature-rich. Some potential trends include:

- Smarter Displays: Future displays may integrate AI to provide predictive maintenance data or adjust display settings automatically based on the environment.

- Touchscreen Capabilities: Touch interfaces are expected to become more common, allowing for easier interaction with industrial systems.

- Higher Resolution and Color Displays: Advances in display technology may lead to more vibrant and higher-resolution screens suitable for complex data visualization.

Conclusão:

Industrial serial LCD display play a pivotal role in modern industrial applications by providing real-time data in a clear and efficient manner. Their energy efficiency, ease of integration, and ruggedness make them essential in environments ranging from manufacturing floors to remote monitoring stations. By understanding their working principles, advantages, and applications, you can better leverage these displays to enhance operational efficiency and streamline processes.